First time right

Functional

Safety

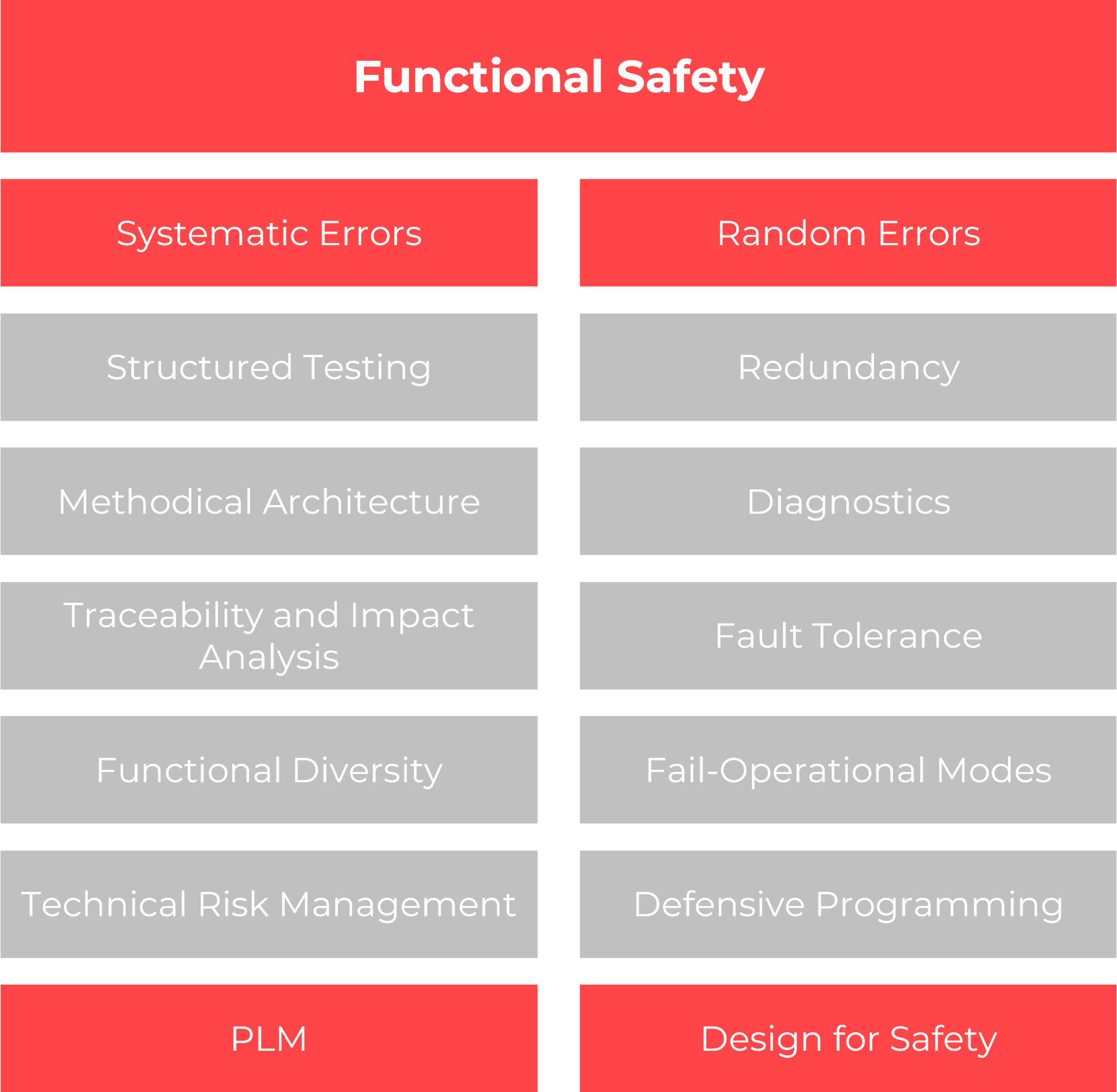

WHAT IS FUNCTIONAL SAFETY?

Functional safety refers to the part of the overall safety of a system that depends on the correct functioning of the safety-related E/E/PE (electrical/electronic/programmable electronic) systems and other risk-reducing measures. It can involve machines, software, hardware, or entire installations, which could potentially cause hazardous failures in the event of malfunctions. A distinction is made between the "normal function"—the intended function—and the safety-relevant part of the system, the SRP, which enhances the normal function to make it a safe function.

Standards and Regulations

Functional safety standards such as IEC 61508, ISO 26262, and various industry-specific standards define the requirements and procedures for achieving and assessing functional safety. Each industry, from medical devices to the automotive sector, has specific standards that set the framework for development processes.

System Characteristics and Efforts

Adhering to the specified standards and necessary risk minimization is crucial, with particular attention to the Safety Integrity Level (SIL). The primary focus is on preventing systematic errors during the development phase, achieved through the use of methods and structured processes, such as reviews, as well as through verified tools and toolchains. This process is overseen by safety management. Additionally, comprehensive, complete, and revision-secure documentation must be prepared to demonstrate compliance. Depending on the project, control over random hardware failures must be ensured within the system design, and adherence to failure probability requirements must be demonstrated through analysis.

Redundancy

A key aspect of functional safety is the implementation of redundancy. Redundancy involves using more than one system to perform a particular function, ensuring fault tolerance. For example, in a 1oo2 approach, two independent, similar systems (channels) are implemented, both operating in parallel during normal operation. If one system fails or malfunctions, the other can continue to perform the intended function safely. This approach is particularly effective in increasing the safety and availability of systems and minimizing the risk of total failure.

PLANNING FUNCTIONAL SAFETY

Risk Management

Contrary to common belief, functional safety is not something that can be "retrofitted"; it begins with systemic design. Starting from technical risk management, hazards and their potential impacts must be assessed. The key concept here is the HAZOP analysis (HAZard and OPerability). HAZOP analysis enables the identification of numerous risks in advance. In the HAZOP context, a hazard is understood as a situation where a real or potential threat to people or the environment exists that could cause an accident.

From there, the product lifecycle and design process determine how these hazards are addressed through technical and safety-related requirements analysis.

Functional and Technical Safety Concept

The functional safety concept focuses on the higher levels of the system and describes the safety functions that need to be implemented to mitigate identified risks and meet safety objectives. It answers questions such as:

- What hazards and risks exist?

- What safety functions are required to mitigate these risks?

- How should the safety functions be fulfilled at the highest level?

In this concept, the safety-related requirements that a system must meet are defined, outlining how these requirements can be achieved by implementing certain functions, without going into the technical details.

The technical safety concept, on the other hand, delves into the specifics of how the requirements outlined in the functional safety concept will be met. It defines how the safety functions are to be technically realized and includes details on:

- Hardware and software architecture

- Selection of technologies and components

- Specific technical measures and protective mechanisms

- Concrete implementations of safety functions

“”

Functional safety is a serious commitment. And yet, it can be enjoyable. When gears mesh and processes unfold effectively, the technical potential of structured work becomes evident.

OUR EXPERTISE FOR YOUR FUNCTIONAL SAFETY PROJECT

Functional Safety Through to Certification

With expertise, we help you achieve your goals with ease—we plan the implementation of functional and non-functional safety requirements with you so that systems and processes align perfectly.

We support you up to the successful certification of your products in the context of ISO 26262 (Automotive), Rail (EN 5012x), General Industry (ISO 61508), and Machinery (IEC 62061).

Our services include:

CURIOUS?

Questions, comments, or suggestions about how we work and develop? We are happy to answer them in a personal conversation. Feel free to send us an inquiry about your concerns.

We look forward to hearing from you.

Dr. Hendrik Schnack

Sales, Technology

Hummam Kadour

Account Management